We often get asked ‘How do you buy or create a theme park ride at Sundown Adventureland?’

Well, let me tell you first of all it’s the most fun things to do in the world! But it’s not as simple as nipping to the shops and grabbing one of the shelf (Even if we were allowed to wander to the shops……)

There is a lot of work involved before we can even buy a ride or start creating one. I’m going to keep this as simple as possible for any younger readers to follow too, as the rides are designed for them!

So, I thought it would be fun to show you the main principles of how we planned, constructed and opened the new Wild Ostrich Safari Ride. Let’s get started.

There are five main stages to build a ride.

- Concept Planning

- Main planning (lots of thinking to do before the building can start)

- Clearing the site

- Construction (Yeah finally time to build)

- Testing, training and opening

We also had four main companies or contractors responsible to help build the ride

- Main contractor for the ground works and steel fabrication for the pre-ride area

- The ride manufacturers

- A theming company

- Sundown Adventureland maintenance team

Concept planning

Concept planning is a fancy word which means everybody thinking of new ideas and how we are going to build the ride. Some ideas can be really good and other ideas are not. The good ideas will be used later on for the main planning stage and used to make a ride.

At this stage we need to think about what we want and how it might look like. After we’d been through this, how did we end up with an Ostrich?

- Story boards – These help you plan what you want to see around the ride.

- Sketches – lots of these help decide what you think will be a good or bad idea

- Selecting the ride company – There are a number of different ride manufacturers and all offer different ride types. We look through their portfolios and meet them to talk about our ideas to try and find the best partner to work with.

- Ride capacity – How many people can ride on it every hour or in a full day? Is that enough to make sure everybody gets a chance to ride on it and nobody misses out because there isn’t enough time.

- Cost/budget – We also have to consider what we want and what we can afford. We have all been out shopping and sometimes seen something nice that is too expensive!

How did we decide on an ostrich?

First of all, we need to decide on a theme that would look and work well within the area that is already in place.

The Angry Birds play area is next to the ride location, so it had to be bird themed.

There is also a sand pit next to the new ride as you walk towards it so…….

If you think of the sands of Africa and the only bird big enough to ride is an Ostrich, then the decision was made.

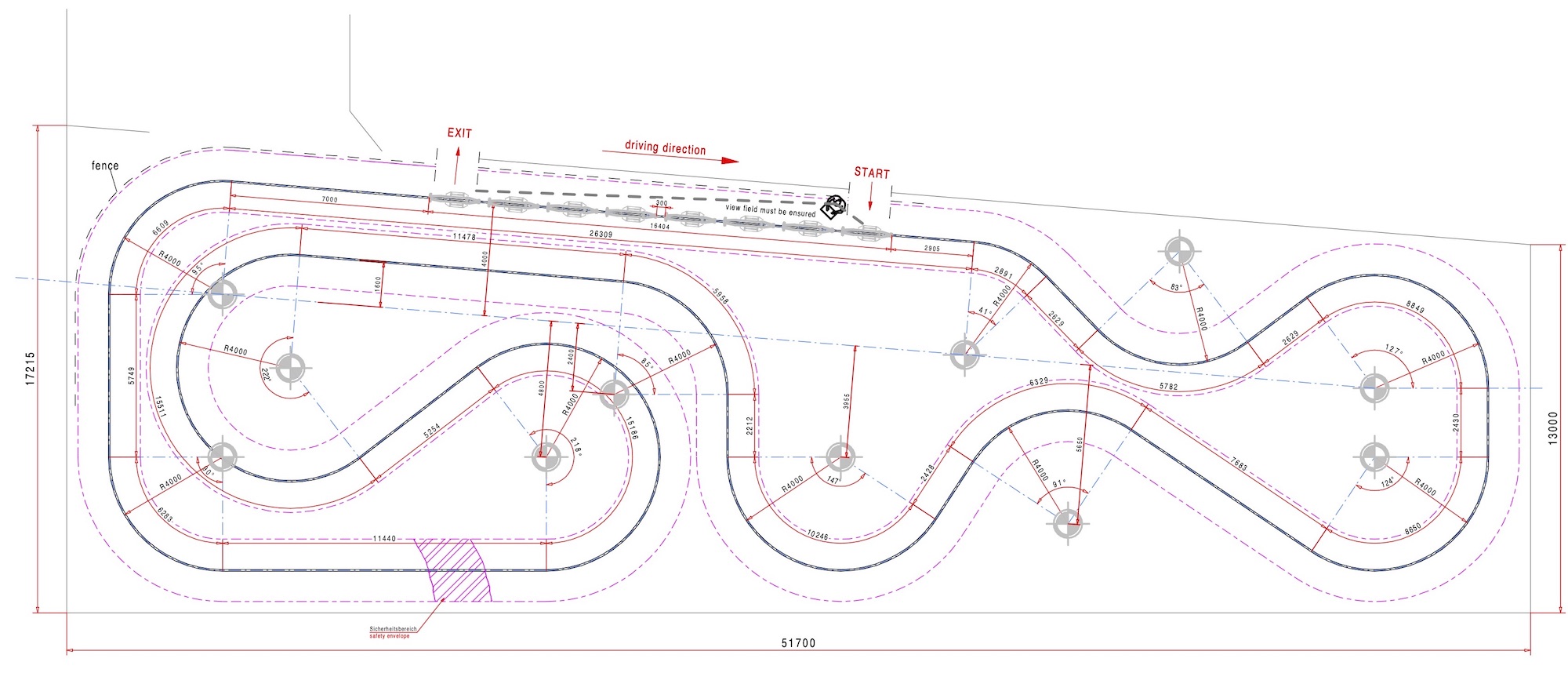

Next, we contact ride manufacturers and see which ride we think will work best. Once we decide what type of ride we want. The manufacturers start planning the layout of the track and where all the services need to be for power. This is the engineering underneath the ride that you may never even notice.

We also speak with ride theming companies who create the characters and all the fancy bits on a ride. They cover up the all the mechanical stuff and make our rides look great.

Then we work with a building contractor to carry out the ground work and the steel fabrication for the loading or pre-ride area.

Some other items to consider…….

- Footpath to access the ride.

- Perimeter fencing to keep guests safe and out of the ride area.

- Lighting for winter months so we can run the ride during Christmas.

- Planting and trees to suit an African theme that will survive in the UK.

- Power supply, new rides need a lot of electricity to run and we need to make sure we have enough available in the area!

- What will the ride be called?

At this stage we first start having meetings with all the people involved to discuss what we need and how we think it will look.

The first meeting we have is with the ride manufacturer after deciding which one we want to work with. We then discuss if the ride is correct for the age group that we have visiting the park, how many people can go on the ride in a day and that it is different to what is already in the park. It helps with planning for everything else if you know what ride you are working around first! We also discuss what the vehicle will look like (the Ostrich) and what space is available to fit the track in so that they can come up with ideas for a track layout.

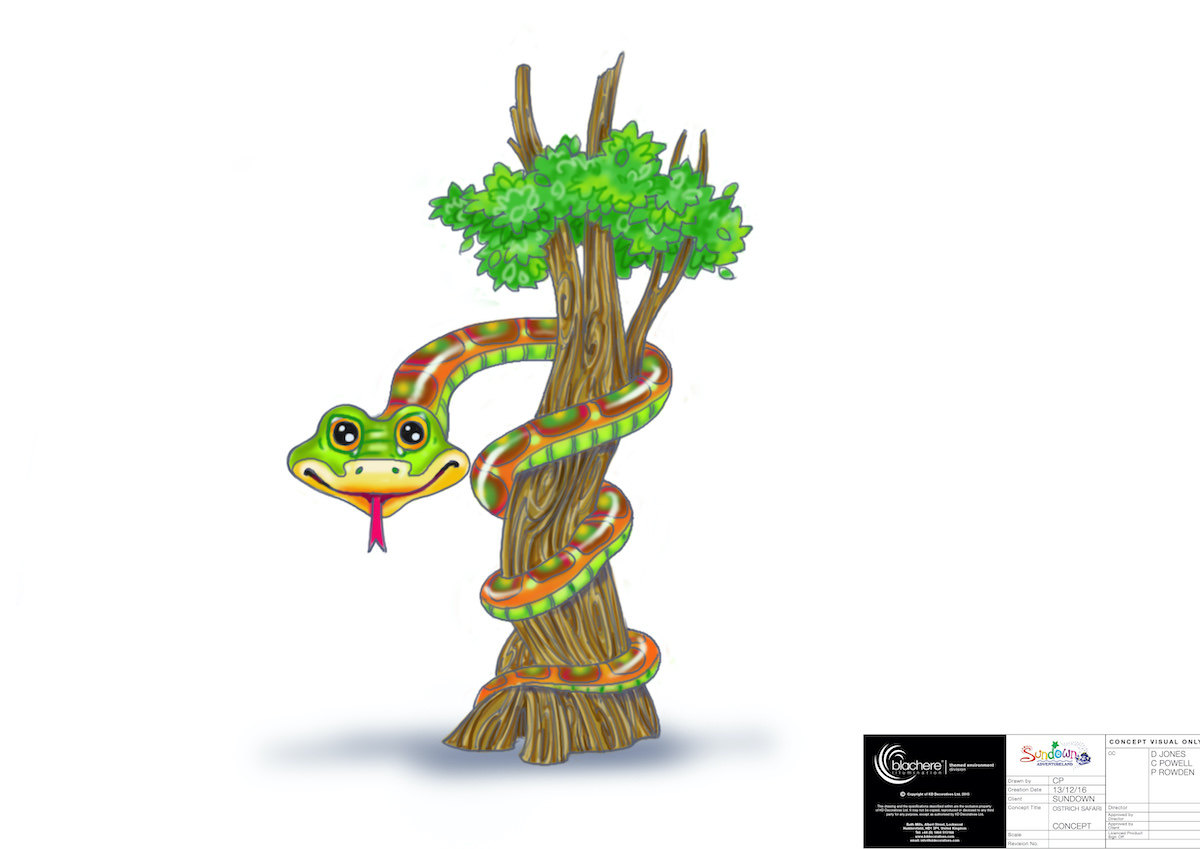

Then we meet with the theming company show them the ride we have decided on. Then we can start to think how it is best to make the ride look good. The theming company will then go away and draw up some lovely concept artwork to show what the characters might look like.

Finally, once we have decided on what ride we want and what we’re going to build, we have a meeting with the building contractor. So that they can start planning what tools/machinery they will need and how much time it will take.

Main planning

This is where we select all the best bits from the concept planning and put them all together and make sure everything will work together. It’s kind of like making sure you have all the right ingredients and add them in the right order to bake a perfect cake!

Let’s talk about the theming company, after we have seen their concept art. They make us 3D renderings which is another fancy word for a mini video. This shows what the characters will look like in real life. We can see the good, the bad and the ugly! We can see what all the characters will look like before they are even made. It really is quite good. So, if somebody’s nose is too big or their feet are too small it can be changed before anything is built or has to be thrown in the bin. This is when we decide the characters we like and will be made for the ride and the ones we don’t like and won’t be used.

Once we know which characters we are using. We can make sure the script for the ride is good and make any final changes ready for recording it later on.

We also need to discuss with the ride manufacturers to make sure the track will fit and that there will be enough room for all the new characters and any buildings without it being too close to the track and becoming dangerous. This is when we make a final decision on what the track layout will be.

…and what the ostriches you ride on will look like.

Now we know what everything is going to look like and where it will all be placed around the ride. We put all the final plans together with the main contractor and the Sundown maintenance team to make one big master plan. This is when we discuss lots of things that need to be thought about before we can start work.

Such as where the lighting needs to be for when it is dark and where we need to dig trenches for water, electric and air supply to make everything work later on. We also need to think about the planting its not easy trying to plant an African-ish garden in a British climate!

Clearing the site

Before we can start to build the new ride, we need to remove what was there first! And make it safe so that people visiting the park are not in any danger or anybody working on the site can do it safely. There used to be a pedal go-cart track so there wasn’t too much to remove. There were just two little houses that the go-carts lived in at night-time, some benches and fencing alongside the retaining walls and tyres that were around the track. This didn’t take too long to clear ready for the building to start.

Let the construction begin!

So now the theming company is making all the characters which are cut out of foam blocks with a big fancy computer and they then hand carve any tiny bits of detail before they are covered in fibreglass and painted.

The theming company are also busy recording the script which means finding the right people for the voices, so it sounds great and also making background noises and some music to go with it.

We also go along to their workshop to see how the process is carried out and most importantly that everything is on time and looking great. (which it was!)

The Contractors along with the sundown team are very busy digging out the site ready to lay all the ducting for the electric cables, air lines and water. As well as putting down hundreds of tonnes of stone for the new ride track to sit on. The contractors also start making the steel frame for the pre-ride area.

Next, the ride manufacturers come to build the track. With most of the work done in their workshop, this happens very quickly, and is built in a week. Then they go back home to Germany and will return later, to finish it off.

Now that the track is in place, even more stone is put down to bury the track so it can’t move and hold it in place. We can now start running air and electric to where it needs to go. And start laying the concrete pads for all the buildings, arches and characters to sit on. The steel frame for the queue area starts to go up and the concrete paths are laid. We also lay the rubber mulch around the track so it looks tidy and hides all the stone.

After about a month the Ostriches arrive from Germany and the ride manufacturer gets them sat on the track and start wiring up the electrics and getting the ride up and running.

The theming company now arrive and start installing the archways and the characters everything is starting to come together now.

Now is the time for the finishing touches, such as the lighting around the ride, all the planting and the fencing is all installed. The canopy over the pre-ride area is almost finished too.

Testing, Training and opening

Once each company has finished, they need to test everything is working correctly. So, the theming company needs to make sure that the characters move when a sensor tells them an ostrich has moved past. They also need to make sure the recorded script is in perfect time with all the animation, so it sounds great too.

The ride manufacturer has to make sure that all the Ostriches start and stop when they are supposed to and that they are all travelling at the correct speed.

The electrician has to test all the wiring to make sure everything is safe and that all the emergency lighting works.

Then once everybody is happy that it all works, we need to get a certificate from an ADIPS inspector to say that everything is safe, and people can use it. Think of it like getting an MOT certificate for your car and yes it has to be retaken every 12 months.

Now we can train our maintenance team. It’s their job to inspect, service and repair the ride and then train the operators how to run it. The book for this is very big!

And then after 3 months of planning and another 5 months of construction…..You have built a new shiny ride for everybody to enjoy.

And if you’d like to join us on a ride aboard the Wild Ostrich Safari Ride, then hop aboard and here we go!

Recent Posts

Archives

- June 2025

- May 2025

- April 2025

- December 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- April 2024

- March 2024

- November 2023

- October 2023

- January 2023

- August 2022

- July 2022

- September 2021

- March 2021

- September 2020

- July 2020

- May 2020

- April 2020

- March 2020

- February 2020

- July 2018

- April 2018

- March 2018

- February 2018

CLOSED ATTRACTION NOTICE: Lollipoppet Castle is closed for refurbishment and will reopen in the summer.

CLOSED ATTRACTION NOTICE: Lollipoppet Castle is closed for refurbishment and will reopen in the summer.